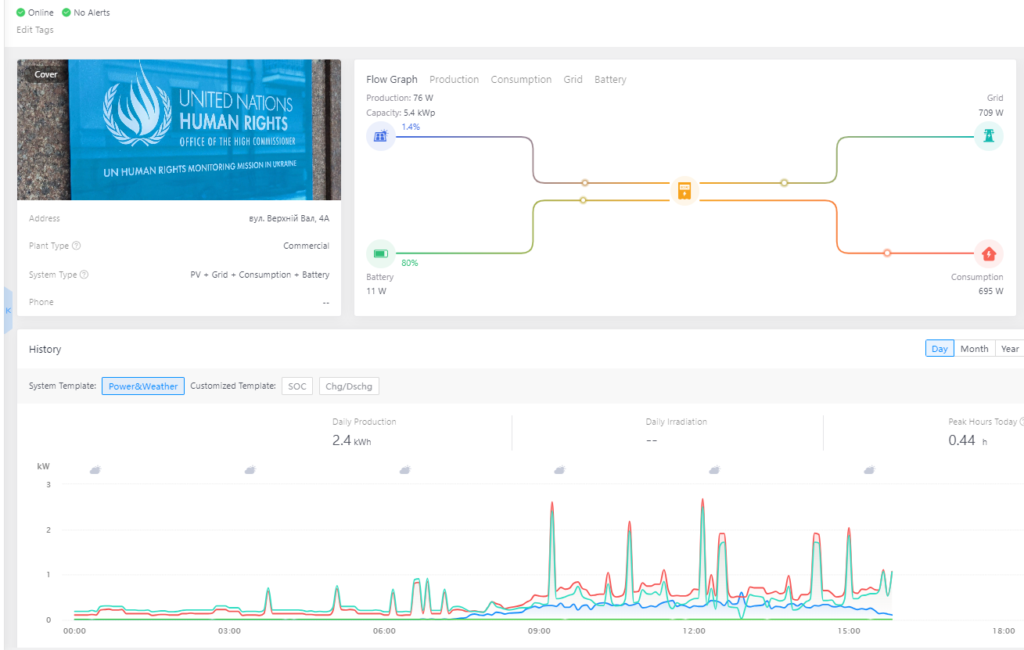

Friends, Alteco helps international organizations become energy independent and save money on energy resources.

This time, the THE UNITED NATIONS HUMAN RIGHTS OFFICE IN UKRAINE joins our clients.

The organization experienced power outages and rising tariffs.

Therefore, the integrated solar hybrid power plant turned out to be the best way to save money and stabilize the work of the staff.

The features of this project were:

- integration of the equipment into the already existing system of the building’s electrical management;

- location of solar modules in conditions of their shading from nearby existing objects;

- lifting equipment to the roof and installation in conditions of dense urban development.

In addition, the Organization occupies only a part of the area of the office center, which made it necessary to work more carefully on the electrical networks of the site.

After analyzing and separating the electrical loads, Alteco specialists integrated the solar plant equipment in such a way that only our client’s equipment was powered.

As always, the responsible parties have access to the solar generation and energy monitoring system from the existing supplier.

Short brief of equipment installation

Unloading of equipment and fencing of the territory.

To prevent injuries to passers-by during the installation of the SPP on the roof of the building, the working areas below are fenced off.

The process of lifting the equipment to the roof requires special attention.

Therefore, solar modules of a smaller size were specifically used, which allowed to use the existing receptions / elevator of the building and increase the level of safety of personnel working at height.

The size of the solar panel is 1722 * 1134 mm, allowing the use of an ordinary elevator.

Installation of safety cables for the work of specialists and lifting of equipment.

Fixing solar modules and pushing them through the window.

In some European countries, it is even forbidden to install large-sized solar modules on the roofs of buildings.

In priority, for pitched and small roofs, using panel sizes up to 1750 x 1134 mm, weighing up to 20 kg.

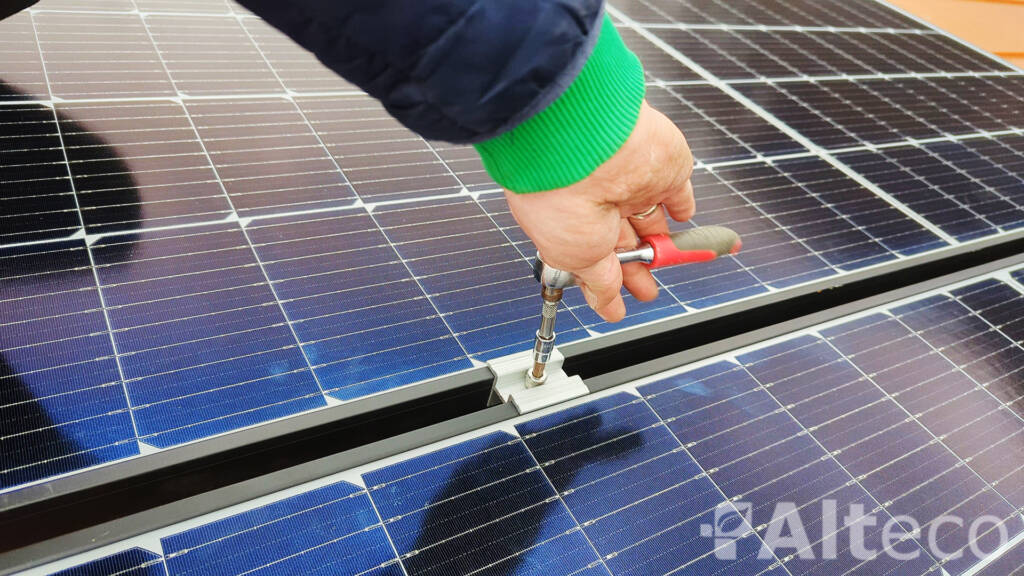

Preparation and marking of the roof covering for the installation of PV modules.

In this case, we were dealing with a folded metal coating.

Special clamping fasteners are used for the folded roof.

Special aluminum guide rails are mounted on the clamping fasteners.

The rail is connected to each other by additional elements.

The finished rails are the basis on which the solar panels will be mounted.

This mounting system allows you to adjust the aesthetic of the entire row of panels and has a gap between the roof and PV modules for ventilation and cooling of the modules.

Aluminum fasteners also have an advantage – this is a reduced load on the roof compared to galvanized metal.

All rows are aligned and ready for solar panel installation.

A special solar cable with protection is laid to the PV modules.

The place of laying communications is determined in such a way as to prevent leaks.

All panels are placed on prepared rails and also fastened with special clamps.

A clamp specially selected for the thickness of the panel frame is also mounted between the photovoltaic modules.

In this way, the entire projected row of solar panels is filled.

Alteco company is a complex implementation of Clean Energy projects. We provide consulting, EPC contracting, operation and service of alternative energy facilities. Our specialists are always happy to discuss your project.