Alternative energy facilities are a new direction in project design (engineering), construction and operation. Engineering requires of one specialists, construction – of second, and operation, respectively, of third. New technologies, solutions and approaches are constantly coming to each of these areas. Despite the novelty of this direction, the same laws and rules apply in the organizational plan as in conventional construction – this is a division into stages:

- project design (engineering);

- supply of equipment and materials;

- construction;

- operation.

If you ask specialists in each area of how the facility should look like, then each will give his own vision and understanding of what needs to be done and will assume that he is right.

When dividing a project into appropriate stages, it is very common for the Customer / Investor during construction to have difficulties with the implementation of solutions that were laid down, for example, at the engineering stage, and operation stage is confused after the builders.

For example, the technical solution is already outdated, the range of equipment has changed or it is difficult or expensive to physically fulfill the decision at the facility, and the project design is ready. All this is superimposed on the division of responsibility of contractors and the timeline for clarifying “How to do this?” Or “Who is to blame and how to redo this?”, At a time when the project design phase is already completed and the contractor does not want or does not know how to solve the problem. If we add questions and misunderstanding from the operating department here, the final picture is often not as colorful as it seemed to the Customer at the very beginning of the journey.

As a result, the Investor goes beyond the planned budget and deadlines for the implementation of his business project. There are many examples with final losses and the correctness of each of the parties, where everyone points at each other, hiding behind building codes and legal formulations in contracts. As a result, the customer remains on his own with his problems and losses.

To solve these problems, the general contract or the EPC-contract was implemented (Engineering, Procurement and Construction).

In this case, the EPC-contractor company assumes all functions – project design (engineering), equipment / materials supply (procurement) and construction of the Customer’s facility.

All risks associated with errors in the project design documentation, changes in technical solutions, procurement of low-quality materials, terms and quality of construction in this case are borne by the EPC-contractor.

As a rule, knowing full responsibility, EPC-contractor is already on the engineering stage is trying to do his job efficiently and lays down those decisions that he can also perform qualitatively during construction. The correct preparation of technical specifications for geotechnical / geodetic surveys, suppliers of equipment / materials, quality control, timing, also lies with the general contractor.

Particular attention at the stage of general contracting lies with the performance of works by related and narrow-profile specialists (for example, geologists, topographers, ASCEM and external networks for the facility). So, the whole construction facility and the convenience / cost of operating it in the future depend on the quality of their work.

According to the working experience, it can be noted that sometimes you need to stand “over the soul” of the performer day and night in order to achieve the result that everyone needs.

As a rule, the final benefit for the Customer is:

- lack of headache in coordination of dozens of specialists and contractors;

- declared quality of work and a comprehensive guarantee for the facility;

- confirmation of the agreed construction term.

In other words, working with the general contractor for the Customer should be faster, better and cheaper – or why then the Customer needs an EPC-contractor.

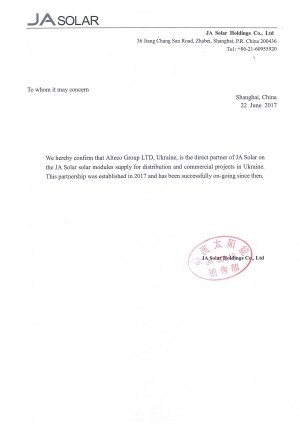

At present, Alteco Group provides general contracting services for the construction of solar power plants throughout Ukraine. Working as an EPC-contractor, we have shown our effectiveness in many facilities of SPP. Following our principle of “do such as for yourself,” we know exactly how to save the Customer’s time and money.